-

-

- The Group enters the business of electrically powered heavy vehicles with an OE supply

- Development of an aluminum cooling module using vacuum brazing technology

- Prolonged service life of the transmission system, contributes to reduced vehicle energy consumption

-

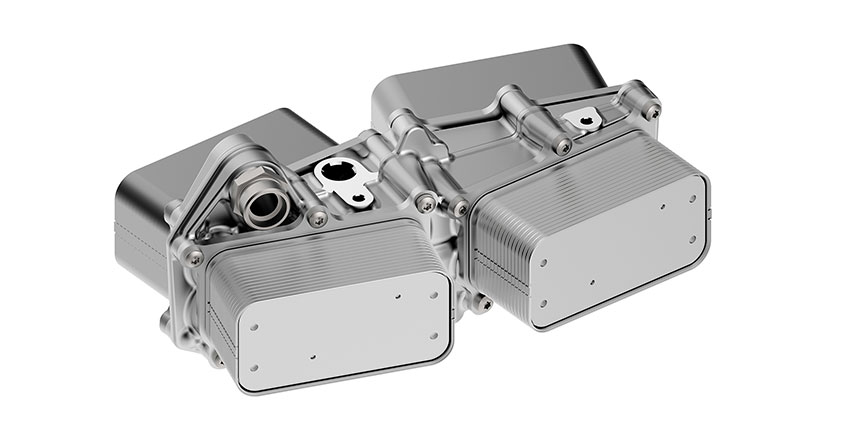

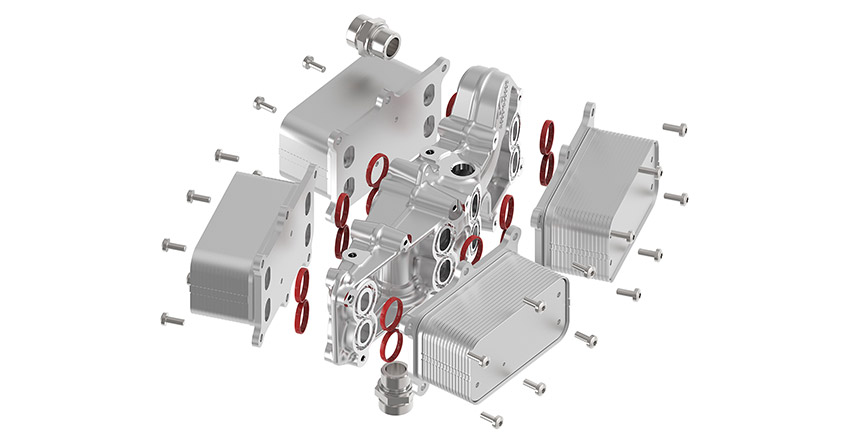

UFI Filters, a leader in filtration and the production of heat exchangers for combustion, hybrid and electric vehicles, takes an important step towards electric mobility with the OE supply of the cooling module (multi heat exchanger) for the transmission oil of a fully electric series-production truck from Daimler Truck AG. This development marks the Group’s entrance into the business of electrically powered heavy vehicles.

The UFI cooling module interacts with the transmission oil circuit of the e-axle, combining two integrated electric motors, which together generate a continuous power of 330kW, with peaks of up to 400kW.

The module was developed together with the German maker and is manufactured by UFI Filters at its plant in Opole, Poland and consists of two pairs of heat exchangers operating in parallel and assembled on a single aluminum body.

The UFI module has the fundamental task of optimising the oil temperature of the transmission circuit. UFI heat exchangers, made from aluminum and using modern vacuum brazing techniques, ensure a longer service life for the transmission system thanks to their high efficiency and help to reduce overall vehicle energy consumption.

Rinaldo Facchini, CEO of the UFI Filters Group, comments: “We are extremely proud of this project, which opens the door to the development of the business in the field of electrically-powered trucks. With the development of modern aluminum heat exchangers produced in our dedicated European plant, we are making an important step towards ecological sustainability. In addition, UFI Filters once again confirms itself as a partner to the largest manufacturers. Along with our innovative solutions for today, we are also at the forefront in terms of new technologies for the mobility of the future, which further strengthen our OE pedigree.”

- The UFI cooling module interacts with the transmission oil circuit of the e-axle, combining two integrated electric motors, which together generate a continuous power of 330kW, with peaks of up to 400kW.

The module was developed together with the German maker and is manufactured by UFI Filters at its plant in Opole, Poland and consists of two pairs of heat exchangers operating in parallel and assembled on a single aluminum body.

The UFI module has the fundamental task of optimising the oil temperature of the transmission circuit. UFI heat exchangers, made from aluminum and using modern vacuum brazing techniques, ensure a longer service life for the transmission system thanks to their high efficiency and help to reduce overall vehicle energy consumption.

Rinaldo Facchini, CEO of the UFI Filters Group, comments: “We are extremely proud of this project, which opens the door to the development of the business in the field of electrically-powered trucks. With the development of modern aluminum heat exchangers produced in our dedicated European plant, we are making an important step towards ecological sustainability. In addition, UFI Filters once again confirms itself as a partner to the largest manufacturers. Along with our innovative solutions for today, we are also at the forefront in terms of new technologies for the mobility of the future, which further strengthen our OE pedigree.”